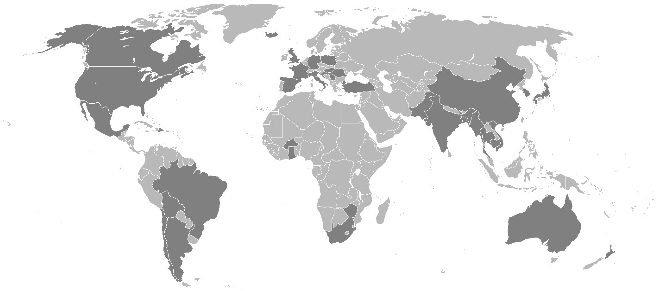

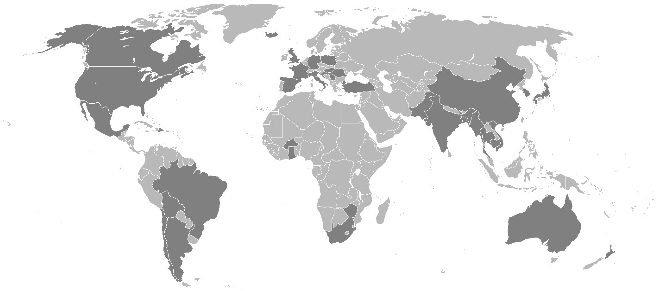

Arsenic-affected countries of the world (Smedley and Kinniburgh, 2002; Appleyard et al., 2006; Petrusevski et al., 2007; Smedley et al., 2007; Gunduz et al., 2009; Jovanovic et al., 2011)

DMI-65 is a key part of new technologies based on the co-precipitation of arsenic in flocs during coagulation and arsenic adsorption to the media. If water has Arsenic present but no Iron it will be necessary to add ferric chloride (or ferric chloride) to the water. In all cases the arsenic binds to the positively-charged surface of the Iron (Hydroxide) matrix. DMI-65 is an extremely powerful silica sand based catalytic action water filtration media that is designed for the removal of iron to undetectable levels through an Advanced Oxidation Process.

Especially at low to moderate arsenic concentrations, the technology of arsenic adsorption is very effective. It should be noted that this only applies to inorganic As (As III and V) since not all organic As readily bonds with the Fe.

In a laboratory test, approximately 78 PPB of arsenic and a small amount of ferric chloride were added to uncontaminated well water, which was then run through DMI-65 Media. The results showed that the DMI-65 Media reduced the arsenic from 78 PPB down to < 1 PPB. In full scale applications, the DMI-65 can be simply backwashed with clean chlorinated water and then put back into service. It does not have to be regenerated like conventional green sand media.

Quantum recognises that the highly toxic nature of Arsenic means that there is no margin for error in water treatment and design. Systems that do not address a proven chemical processes, or establish a point of proof conducting a pilot trial may run the risk of miscalculating correct chemical dosing, detention times, and filtration velocities and ultimately inhibiting removal performance increasing the risk of not reducing arsenic contamination to or below acceptable levels. We strongly recommend proof of water treatment plant design through pilot testing to establish correct settings, or the use of already proven DMI-65 based arsenic removal systems. .

DMI-65 is infused technology and not just a surface coating technology, unlike other catalytic water filtration media, which removes the chance of any chemical leaching into the water stream.

In order to begin the process of oxidation of the iron (and manganese) in solution DMI-65 is designed to operate in the presence of chlorine or other oxidant. In this process the oxidant removes electrons and is consumed in the process. The operator needs to ensure that there is a 0.1 – 0.3 ppm free chlorine residual in the effluent water. Chlorine, fed as sodium hypochlorite or bleach (12.5% NaOCl), is the preferred oxidant since it is relatively inexpensive, readily available around the world and it is effective. It also performs the vast majority of any disinfectant process.

DMI-65 has been certified to the US Standard of NSF/ANSI 61 for Drinking Water System Components and for use in England and Wales Under Regulation 31(4)(a) of the water supply (Water Quality) regulations 2010 and has also been tested by many other water treatment authorities and laboratories.

DMI-65 is manufactured in Australia.

CASE STUDIES

A regional Water Authority provides water and sewerage services to 38 towns, villages and cities serves an estimated population of 95,000 people in an area of approximately 20,000 square kilometers. The communities serviced are diverse in size and characteristics. They range from about 12,300 assessments in to less than 50 in the rural hamlet as well as major industrial customers. The Authority’s two major functions are treatment and distribution, and it operates 30 water treatment sites throughout the region.

The Authority was under significant pressure to ensure that a town of 16,000 people continues to be supplied with treated potable water. The area has suffered severely under drought and the decision was made by the board that North East Water will have to extract and treat bore water for potable water to avoid potential political ramifications.

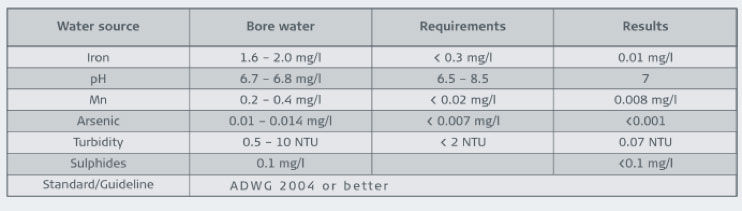

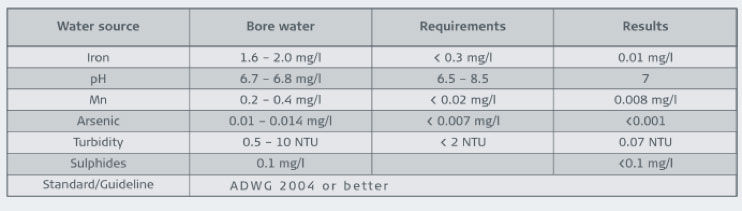

North East Water (NEW) employed the services of Amiad and their subcontractors to ensure quality bore water treatment plants are delivered on time and on budget. NEW propose to utilise two bores delivering 40 l/s (3.5 MLD) each at the Kerr Street site in Wangaratta. Amiad has to design, manufacture and deliver two (2) containerised 3.5 MLD packaged water treatment plants.

The two 3.5MLD water treatment plants deliver treated water that complies and in certain cases exceed the drinking water guidelines.

Amiad designed, manufactured, delivered, installed and commissioned two potable water treatment plants that will consist of two (2) 40ft containers each. Each of the four (4) containers is fitted with four (4) media vessels. Each of the vessels has four (4) valves.

Each of the containers will have to have a separate PLC/Citect control system that will enable Each of the containers will have to have a separate PLC/Citect control system that will enable NEW to use the two 3.5 MLD plants independently or together. Each 3.5 MLD packaged plant must also have the ability to separate into two (2) 1.75 MLD packaged plants. The container housing the controller can then be used as a 1.75 MLD treatment plant as a stand-alone unit.

The Advantages of using DMI-65 in Arsenic Removal Water Treatment

Arsenic Removal DMI-65 does not actually remove the Arsenic but rather relies on the fact that Arsenic and Iron (Fe) readily form a complex and when the media takes out the Fe it takes the As with it. DMI-65 promotes the highest oxidation rate of any catalytic filtration media to achieve the removal of dissolved iron to almost undetectable levels as low as 0.005 PPM. In the correct operating conditions, Arsenic will also be removed to well below guidelines

High Flow Rates. The infused technology of DMI-65 promotes the highest oxidation rate of any catalytic filtration media. This permits a significantly higher water flow rate to achieve the same level of iron and manganese removal. DMI-65 can operate at linear filtration velocities up to twice that of conventional media with a corresponding reduction in capital equipment costs.

High Load Capacity Because of the increased surface area of the micro-porous structure of the matrix material, the DMI-65 also has higher iron and manganese load capacity which can extend the duration of filter runs and the time between backwashing, thereby reducing downtime, operating expense and wastage.

Reduced Costs the total cost of the arsenic removal water filtration system is significantly less than alternative solutions, the effectiveness, but relative simplicity, of DMI-65 based systems reduces the upfront capital expenditure on plant complexity as well as the ongoing operational expenditure in chemicals, power and backwash waste water recovery.

Regeneration Not Required. The media operates with a continuous injection of sodium hypochlorite at low residual levels (0.1 to 0.3 ppm) which eliminates the need for Potassium Permanganate.