BORE WATER ADDITION

It was suggested that the area surrounding the plant be assessed for suitability and potential quality and quantity of several bores to add to the plant raw water supply. The addition of bores would not only provide greater flexibility in terms of seasonal blending with river water to ensure sufficient quantities of water in the dry season, could also be used to lower suspended solids and turbidity loadings on the plant during the wet season.

There is a likelihood that there will be traces of iron and manganese in the bore water, but the use of DMI65 filtration media will remove this and provide an improvement to the usual mechanical filtration duties.

CLARIFICATION

The high turbidity and suspended solids levels in the raw water could be greatly reduced by clarification prior to entering the water treatment plant. The existing plant is fixed in size and capacity, however a pre-clarification stage will dramatically reduce the load on the current plant.

A traditional clarifier and upstream floc/polymer dosing system to handle 1ML/hr would cost well over USD $1M and take up a considerable land area to install and was therefore not practical in this case. With a very low retention time this type of system would also require very high chemical usage.

POLYMER OPTIMISATION

A range of polymer samples were supplied during the site visit. Jar testing has been carried out using the range of samples and highlighted a particular polymer most suited to this raw water. A local polymer supply company is able to supply a very similar product in powdered form and at a very reasonable price that would suit the mixing/batching system mentioned above.

MEDIA CHANGE-OUT IN RAPID SAND FILTERS

During our visit one of the rapid sand filters was drained for inspection. The sand in the filters has never been changed and is now very hard-packed and is in need of replacement. The filter was filled whilst we were watching and the infiltration rate of the incoming water was very poor with most of the water just flowing across over the top of the sand and down through cracks in the hard packed sand rather than down through it. We proposed to replace the media with DMI65® filtration media.

The DMI65 will remove the existing and cope with any rise in iron or manganese levels that can be encountered in raw water sources with varying quality. The DMI65 requires a low level of free chlorine (0.2-0.3mg/L) to activate the media. This is easily achieved as it only requires moving of the existing chlorine dosing point to just prior to the media filters. The chlorine residual will remain and still act as disinfection for the treated water lagoon.

The DMI65® also provides the perfect filtration coefficient resulting in excellent mechanical filtration lowering suspended solids and turbidity levels.

The addition of the DMI media and replacement of the filtration nozzles improved not only the quality of water from the media filters, but also the quantity of water through the filters.

Sample Results

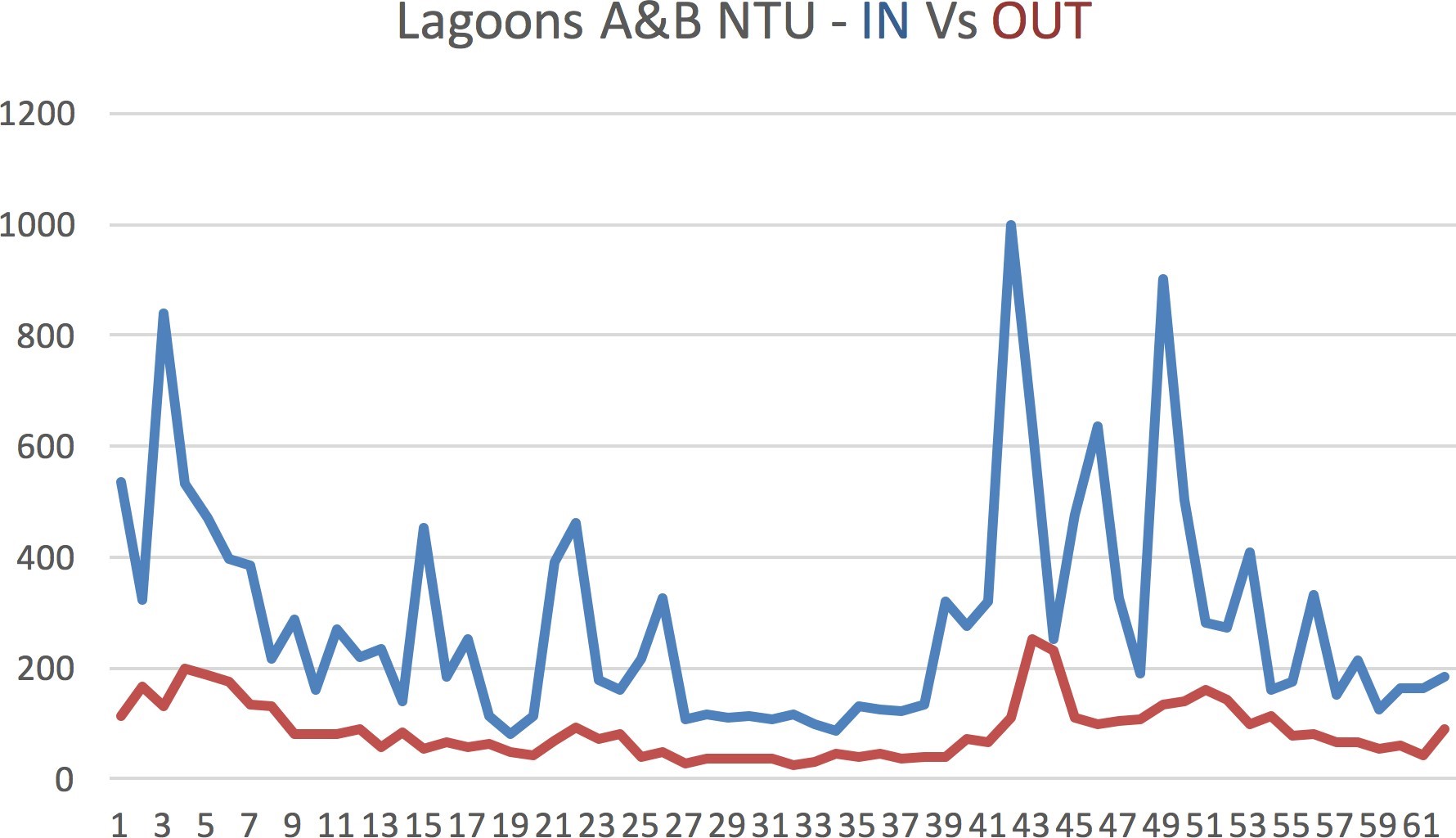

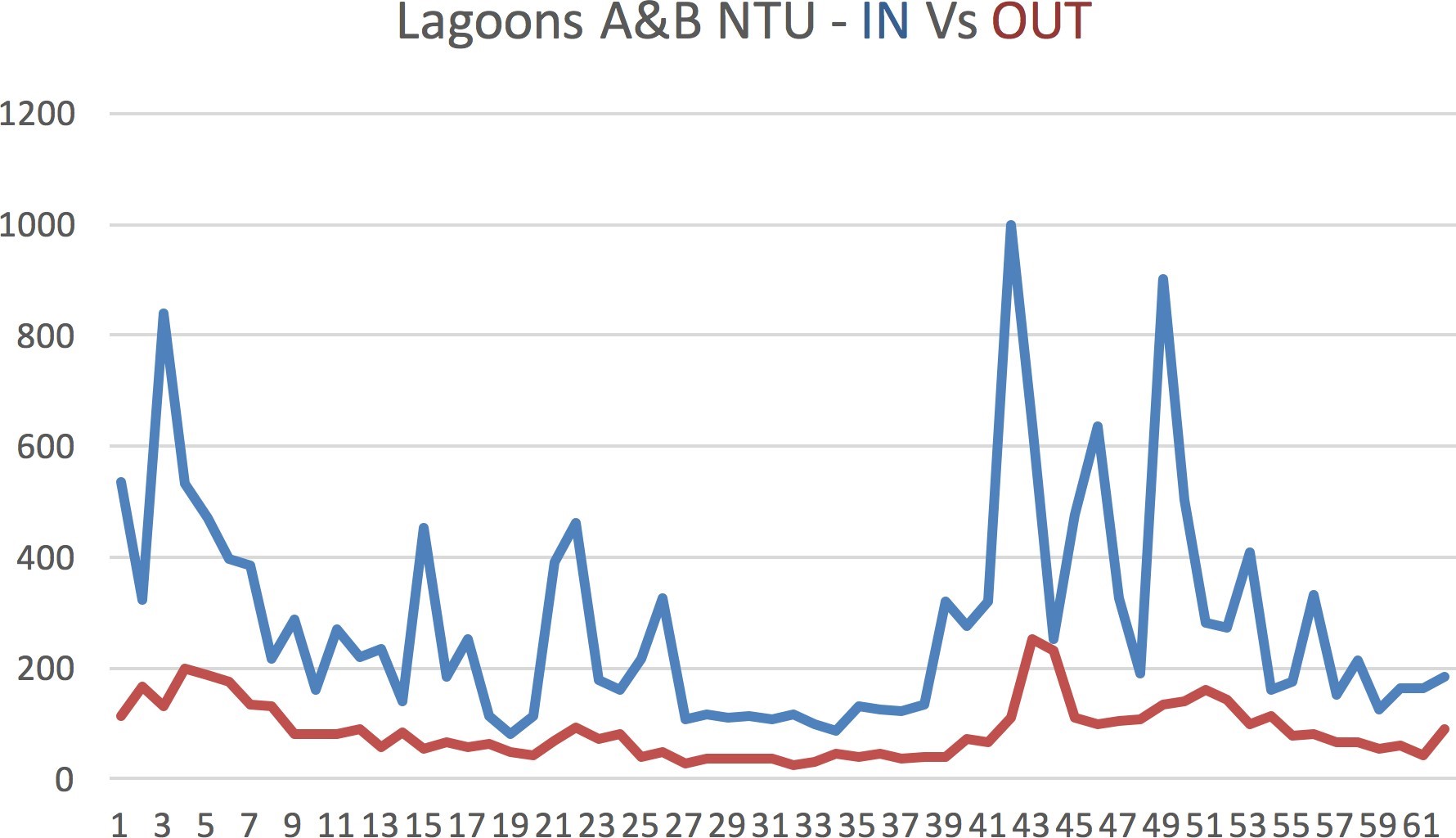

With a peak NTU of 1000 and an average inlet TSS of 286 you can see that the outlet of lagoon B has been maintained generally around 80 NTU with an average of 86 NTU.

OVERALL PLANT OUTPUT

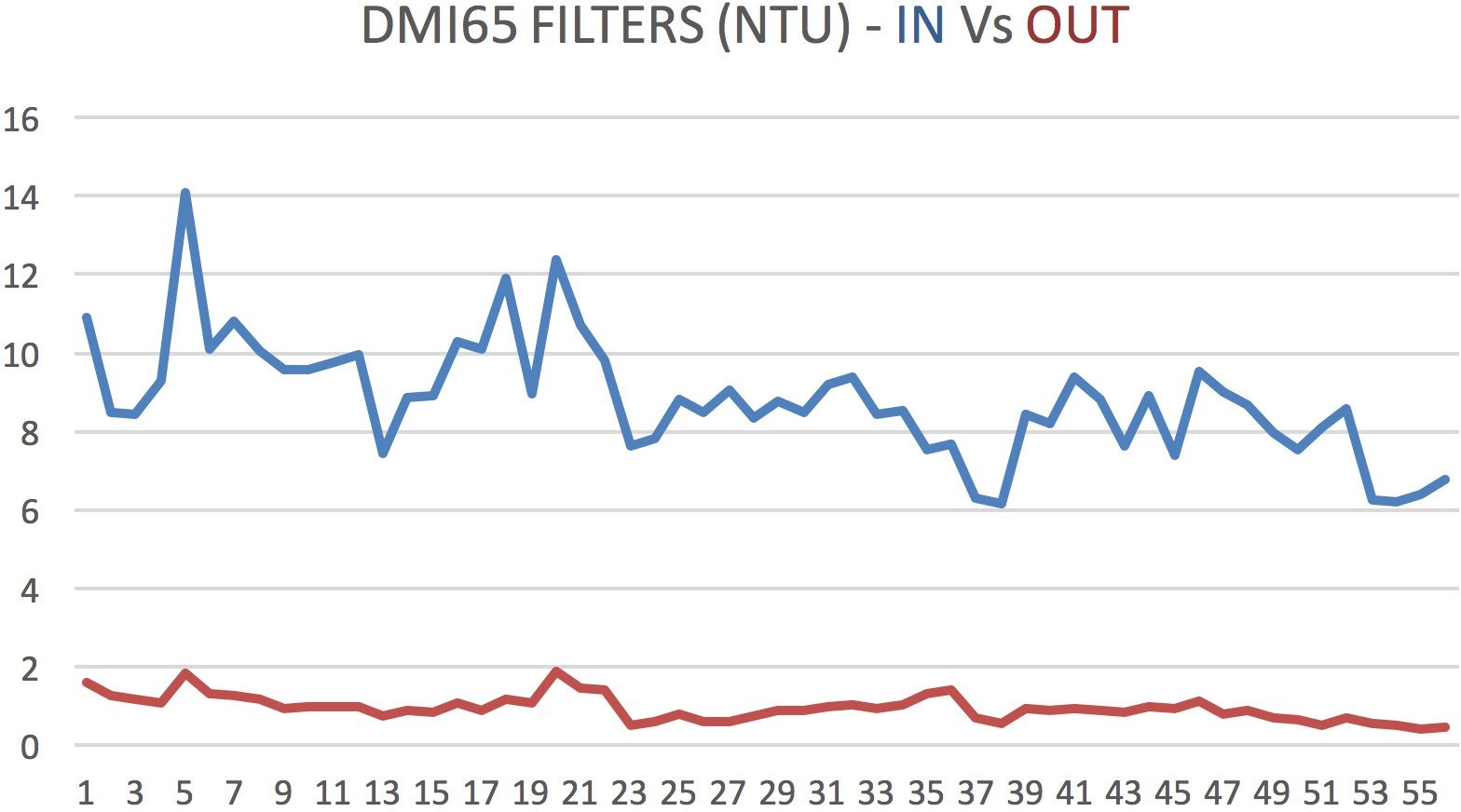

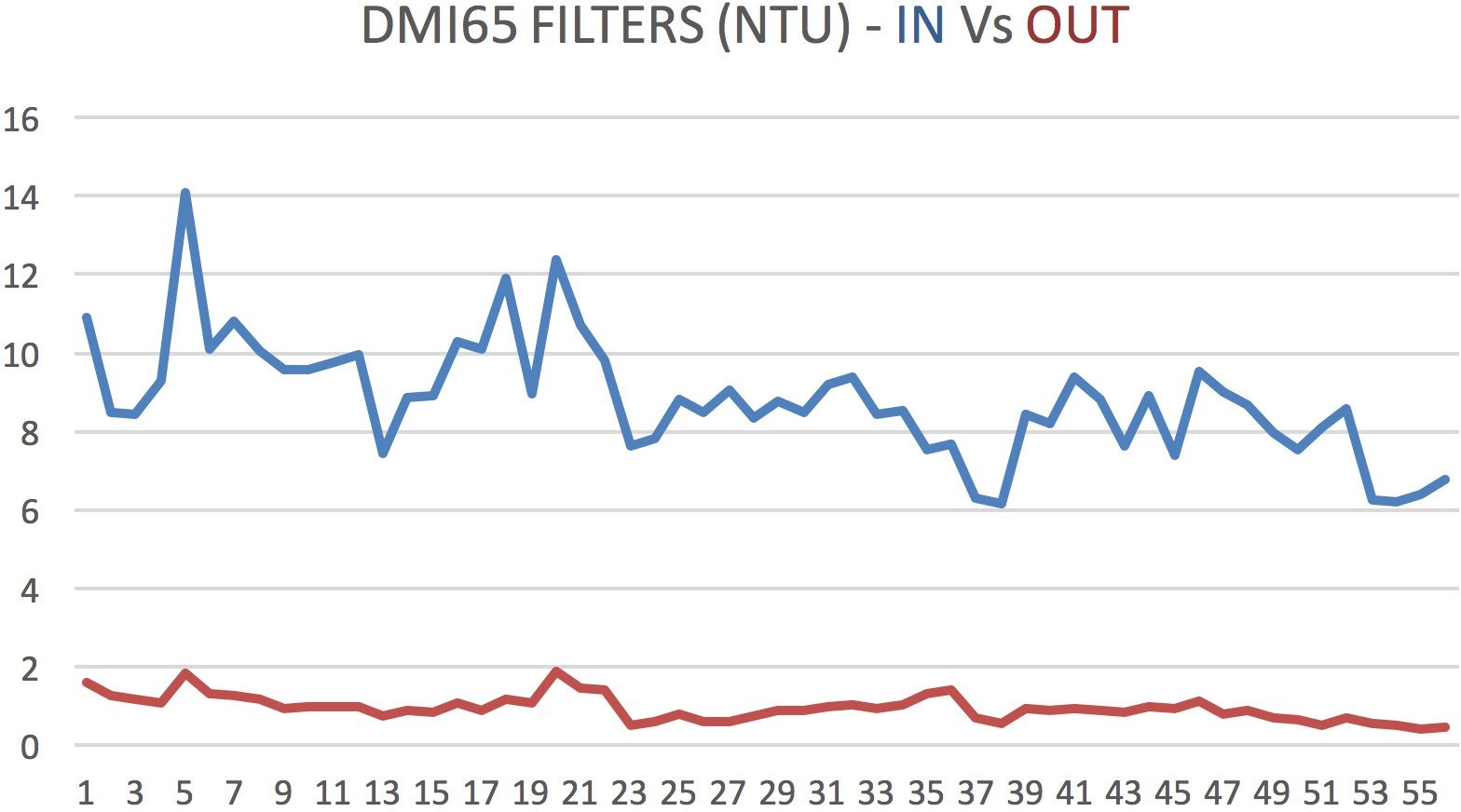

The results from the plant post media filters after the replacement of the old sand media with the new DMI65 media have been consistently excellent.

The expected results from the media filters after the upgrade were:

- TSS < 5mg/L

- Turbidity < 2 NTU

Sample Results

Media Filter Performance – NTU In Vs Out

Summary

Quantum believes that the upgrade has been a success, addressing the main objectives of the upgrade with excellent results.